Product Categories:

4" FLINT & WALLING SUBMERSIBLE PUMP ENDS ONLY

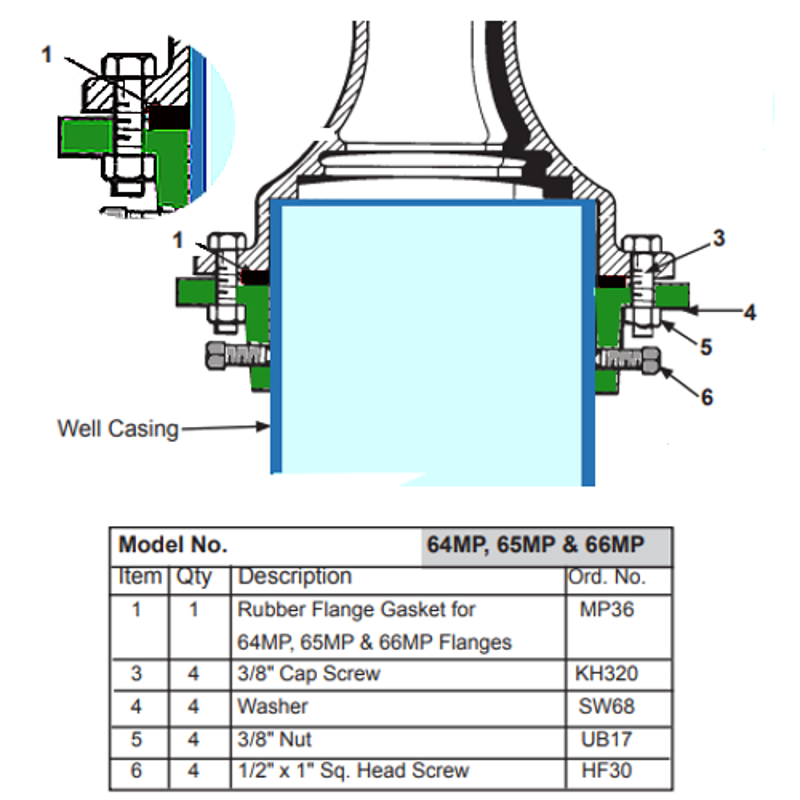

BAKER 65MP 5" Hand Pump Casing Sealed Flange

Return to HAND PUMPS AND RELATED ITEMSThe well casing must extend above the pump platform sufficiently enough to allow 2-1/2" between the bottom of the flange and the pump platform to allow for heaving of the pump platform due to frosts. If a concrete pump platform is constructed, space should be left between the concrete and the well casing so that movement of the concrete platform by frost will not disturb the well casing. This space should be treated as a typical expansion joint. Slip the flange over the well casing. Set the pump onto the casing and bring the flange up to the pump base. Bolt the flange to the pump base and orientate the pump spout to the desired position. Tighten the flange set screws firmly but carefully so that no damage to the flange results. While tightening the flange set screws check for proper vertical alignment of pump.

After the flange has been located and tightened, remove the pump from the flange. Place the rubber gasket in position. If a vermin resistant seal is required place a silicone bead between the outside of the well casing and the pump flange. You may also use plumbers putty or similar product. (not supplied) Place the pump back on the flange and insert the bolts through the pump base and flange, tightening uniformly, thereby compressing the rubber and thoroughly sealing the pump to the flange. An air vent should be provided in the pump stand to admit fresh air to the well. A new pump can be purchased with a vent.

The well casing must extend above the pump platform sufficiently enough to allow 2-1/2" between the bottom of the flange and the pump platform to allow for heaving of the pump platform due to frosts. If a concrete pump platform is constructed, space should be left between the concrete and the well casing so that movement of the concrete platform by frost will not disturb the well casing. This space should be treated as a typical expansion joint. Slip the flange over the well casing. Set the pump onto the casing and bring the flange up to the pump base. Bolt the flange to the pump base and orientate the pump spout to the desired position. Tighten the flange set screws firmly but carefully so that no damage to the flange results. While tightening the flange set screws check for proper vertical alignment of pump.

After the flange has been located and tightened, remove the pump from the flange. Place the rubber gasket in position. If a vermin resistant seal is required place a silicone bead between the outside of the well casing and the pump flange. You may also use plumbers putty or similar product. (not supplied) Place the pump back on the flange and insert the bolts through the pump base and flange, tightening uniformly, thereby compressing the rubber and thoroughly sealing the pump to the flange. An air vent should be provided in the pump stand to admit fresh air to the well. A new pump can be purchased with a vent.

The well casing must extend above the pump platform sufficiently enough to allow 2-1/2" between the bottom of the flange and the pump platform to allow for heaving of the pump platform due to frosts. If a concrete pump platform is constructed, space should be left between the concrete and the well casing so that movement of the concrete platform by frost will not disturb the well casing. This space should be treated as a typical expansion joint. Slip the flange over the well casing. Set the pump onto the casing and bring the flange up to the pump base. Bolt the flange to the pump base and orientate the pump spout to the desired position. Tighten the flange set screws firmly but carefully so that no damage to the flange results. While tightening the flange set screws check for proper vertical alignment of pump.

After the flange has been located and tightened, remove the pump from the flange. Place the rubber gasket in position. If a vermin resistant seal is required place a silicone bead between the outside of the well casing and the pump flange. You may also use plumbers putty or similar product. (not supplied) Place the pump back on the flange and insert the bolts through the pump base and flange, tightening uniformly, thereby compressing the rubber and thoroughly sealing the pump to the flange. An air vent should be provided in the pump stand to admit fresh air to the well. A new pump can be purchased with a vent.

$185.00

12